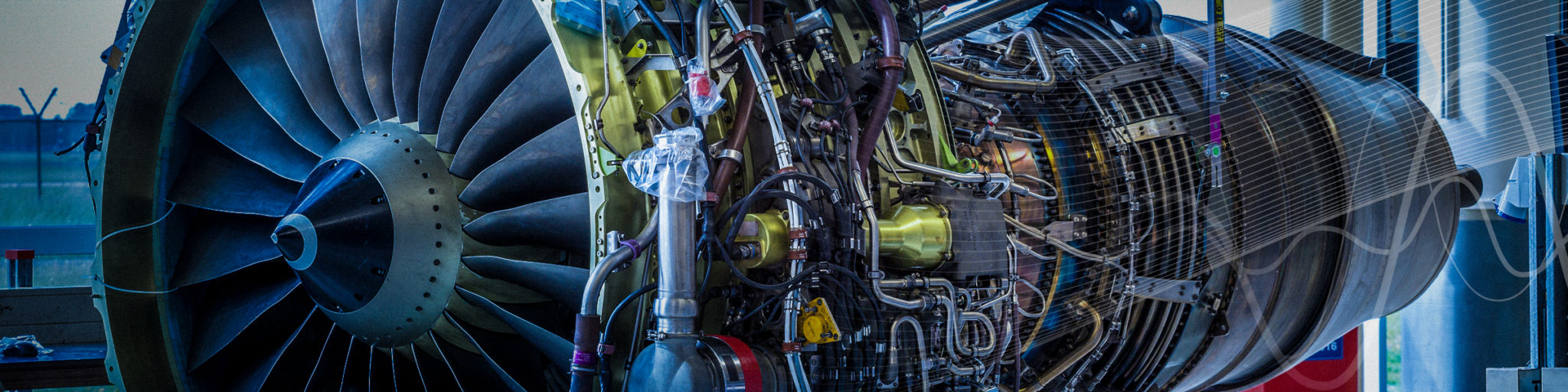

With already harsh engine environments demanding even higher temperature applications, Amphenol CIT provides aircraft Engine manufacturers with the innovative interconnect solutions you need to succeed today.

Our high-performance, lightweight products offer proven, dependable performance in the extremely demanding conditions on and around jet engines, including high-temperature and fire-resistant areas. With solutions for everything from power and grounding, to signal and engine health monitoring, we’re a powerful resource for your aircraft Engine interconnect solutions.

Amphenol CIT’s interconnect solutions have evolved over the years, continually providing smaller form factor and lighter weight products, all while ensuring dependable performance in the extremely demanding conditions on and around aircraft engines. With engine environments increasing in temperature and decreasing in space, Amphenol CIT has aligned its product portfolio with future demands of the gas turbine engine by reducing size and weight without compromising mechanical or electrical performance.

As the industry leader in high temperature wire, Amphenol CIT’s severe environment wires are designed to perform in extremely harsh environments, under vibration and with direct flame exposure. The lightweight engine power feeders, heavy duty lugs and terminal blocks are designed for high temperature and high vibration applications.

Amphenol CIT is one of the world’s leading designers and manufacturers of harsh environment interconnect products including wire and cable, contacts, connectors, cable assemblies, terminals & lugs, terminal blocks and power feeder assemblies.

As aircraft engines power into the future with more sophisticated technology, they also generate more data to monitor. That means more connections. Amphenol CIT delivers the high-temperature wire and cabling that engine manufacturers require to develop these more connected power units.

Our products help provide critical information that allows airlines to precisely determine an engine’s health in real time, and are engineered to withstand harsh conditions such as direct flame exposure. At the same time, our wire and cable systems are ready for the future, with the capacity to handle increased data rates tomorrows engines will generate.

With the increased use of electric architectures, there is an ever-increasing need for extreme reliability and harsh environment interconnect solutions. Amphenol CIT’s grounding and terminal blocks are currently in service on jet engine firewall applications and are custom designed to meet the rigorous performance requirements of our customers. For over 20 years, Amphenol CIT’s wire and cable has been tested and flown on thousands of commercial and military aircrafts offering superior smoke, flame and toxicity performance and enabling it to be used safely in both pressurized and non-pressurized locations. Additionally, our composite insulated cables offer up to a 20% reduction in weight and diameter, without sacrificing the mechanical or thermal performance.

For decades, Amphenol CIT has partnered with aircraft manufacturers to provide cable harnesses and contacts that deliver precise, reliable performance in engine hot spots. As today’s engines move forward in fuel efficiency, they also present increased temperature challenges. Our engineers are ready.

We provide products that push the performance envelope for the high-temperature, high-vibration engine environments in the air today. Our focus has always been on staying ahead of the curve in engine technology, giving manufacturers the support they need to innovate.

To inquire about Engines available from Amphenol CIT, please fill out the form below, and one of our Sales Engineers will contact you.

"*" indicates required fields